“It was by chance, that my manager asked me to meet a new company called Reshape Biotech that approached us.

At that point we were interested in and looking for possibilities of automating our plate counting process. This process requires a lot of manual work to make the plates, large incubation capacity and many, many hours of counting.

We were very interested to downscale the plate counting process as much as possible and move to automatic counting. We have had earlier experiences with liquid handling robots but we have not downscaled the process.

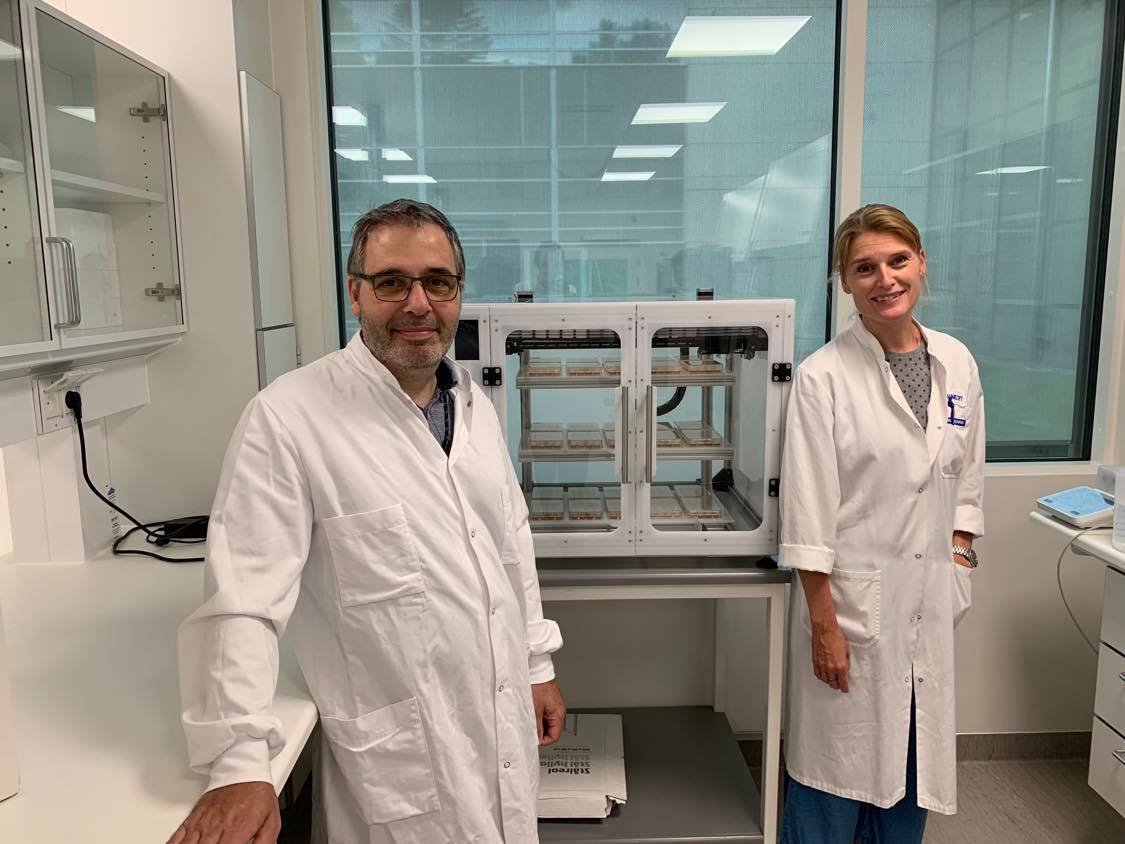

Reshape Biotech visited us and presented their Media Plate Filler claiming it can handle most liquids used in the biotech and food industry. At first look, the ideas were good and close targeted our goals.

We believed though, that it would be very difficult to accurately make small samples in MTP plates, be able to reproduce many copies and keep the quality at a high level at the same time.

We were also worried about the sanitation protocols and the cleaning process especially when working with food analogues as they have their own natural flora following.

But we were proven wrong. We had the opportunity of testing a prototype and we realized how quickly we could produce 24 well format microplates for custom media and food analogues.

Plates were manufactured with great speed and presented a nice surface for spotting. Cleaning processes were tested and plates were incubated for cross and carry over contaminations with no issues. The plates produced with the Media Plate Filler were of the highest quality.

Today it seems that automation of our plate counting process and other microbial growth studies gets one step closer.”

– Jeorgos Trihaas, Principal Scientist at Chr. Hansen